Overmolded Wound Stators

Reduces vibration, thermal rise, and costs; integrate components; offers reliable performance.

Overmolded Wound Stator

- Application: Security Camera, Pan and Tilt Motors

- Magnet Wire AWG 24 to AWG 32

- Multiple lamination stack heights molded in same injection molding tool

- 13mm, 16mm, 18mm, 33mm, 66mm

- Various Features Molded In

- Ball Bearing

- Flange with threaded brass inserts

- Bayonet lock

- Reduced stack up tolerances compared to prior steel and aluminum assembly

- Reduced vibration

- Decreased thermal rise

- Component integration

Overmolded Hybrid Electric Stator

- Application: Automotive Generator

- Resin transfers heat from stator end turns to cooling jacket

- Thermally conductive, electrically insulative encapsulant

- Shut off on large lug termination

- 125 lb stator overmolded

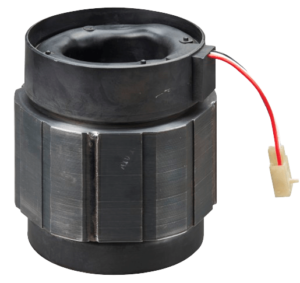

Overmolded Wound Stator

- Application: 48 Frame HVAC Motor

- Molded in ball bearing

- Molded in threaded inserts

- Component reduction

- Eliminate steel shell, aluminum end bell, bearing retainer, lead wire grommet

- Tolerance stack up reduction

- Reduced thermal rise and hot spot temperatures

- Environmental protection for exposed outside use

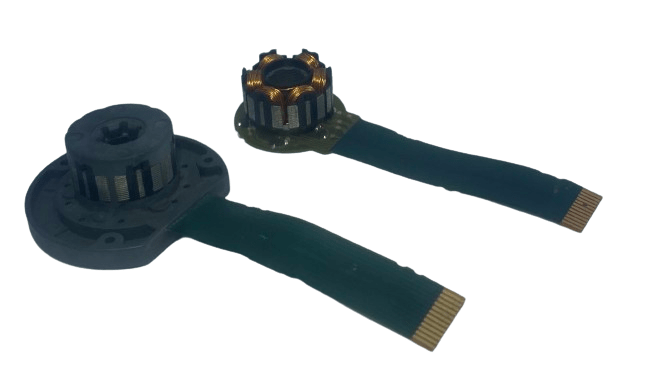

Overmolded Wound Stator

- Application: Explosion Proof Motor

- Shutoff on flex circuit

- Overmolded PCB

- Covers conductors/reduces open space to mitigate explosion risk

Encapsulated Wound Stator

- Application: Natural Gas Pump

- Corrosion protection against natural gas and sulfur

- Prevent electrical failures from debris accumulation between windings

- Surface contour mapped to provide conformal covering of irregular end turn shapes

- Direct shutoff on lead wires

Get in Touch with Our Experts

For more information or to discuss your project, reach out to Encap Technologies. Our team is ready to assist you with advanced thermoplastic encapsulation solutions tailored to your needs.