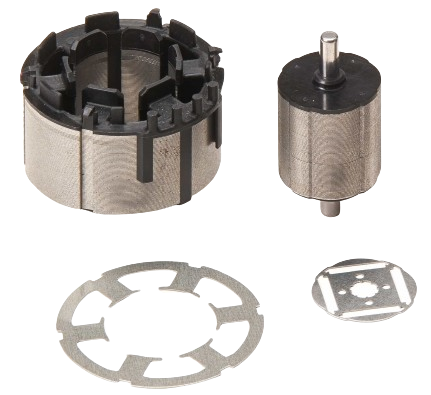

Loose Laminations

"LOOSE" Laminations Ground Insulation

Overview

Loose laminations offer a cost-effective and efficient method for producing certain parts. By eliminating the stamping interlock, both capital and part costs can be reduced by 20-40% as the costly interlock die mechanism is removed and lams are stamped much faster. Lower cost steel can be used and annealed post-stamping to improve performance. The molded ground insulation locks the lams together without the core loss seen with other methods (interlock, clinching, welding) which short each lam to the next.

Cost Benefits

- Reduces lamination stack cost by 20-30%

- Lower stamping die prices

- Faster lamination stamping

- Use of lower cost steel, annealed for better performance

Performance Benefits

- Greater efficiency with reduced eddy current losses

- Eliminates lam-to-lam shorting

- Increased stacking factor and stack density, providing more active material

- Superior pole profile position tolerance, improved back iron contact, uniform pole spacing, lower torque ripple, and reduced cogging

Why Choose Loose Laminations?

Loose laminations not only cut costs but also enhance performance by improving efficiency and reducing electrical losses. This method ensures better material usage and superior component quality, making it an excellent choice for various applications.

Get in Touch with Our Experts

For more information or to discuss your project, reach out to Encap Technologies. Our team is ready to assist you with advanced thermoplastic encapsulation solutions tailored to your needs.