Electrical & Wire Wound Assemblies

Encapsulation for high value coil wound devices, including solenoids, armatures, transformers, bonded coils and voice coil motors (VCMs). Encap’s knowledge and techniques speed time to market and enable world class yield rates.

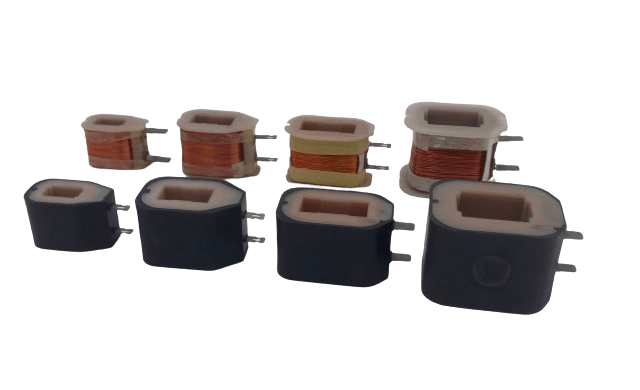

- Application: Solenoids – Turn Key Production Cell Implementation

- Conversion of product line from thermoset to thermoplastic with attendant benefits

- Reduced cost

- Faster cycle times

- Elimination of scrap material

- Elimination of secondary operations

- Enabled 90 second product changeover for High-Mix, Low-Volume (HMLV) production line

- Training and process templates enabling high yield production

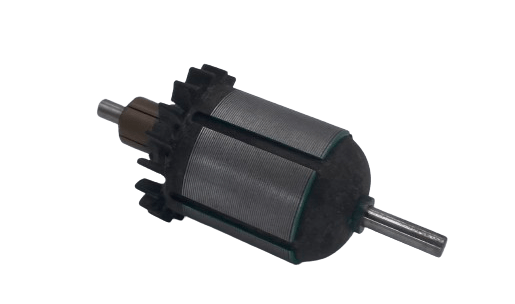

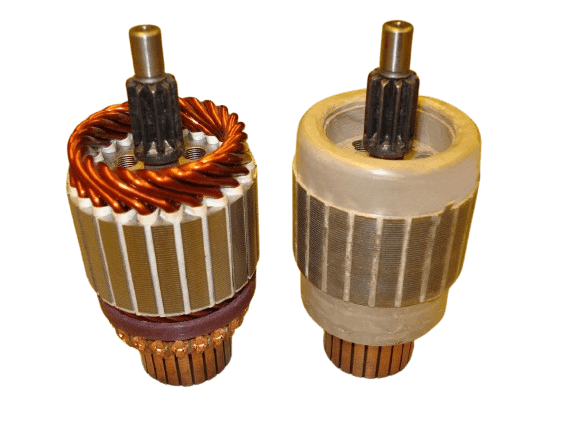

- Application: Power Tool Armature

- Overmolding with thermally conductive / electrically insulative thermoplastic

- Thermal rise reduction in critical commutator area

- Protection of windings from damage from debris

- Improved balance vs. previous slurry winding covering

- Integral fan to cool motor while simultaneously dispersing heat from commutator

- Application: Voice Coil Motors, Hard Disk Drives (HDD VCM)

- Overmolded bonded coils with highly ceramic filled PPS resins and carbon fiber reinforced resins, without electrical leakage or shorting

- High yield rates while encapsulating delicate 28-36 AWG magnet wire

- Thermally conductive thermoplastic reduces thermal rise in magnet wires and reduces computer seek time

- Component integration and mass reduction with development of all-plastic VCM

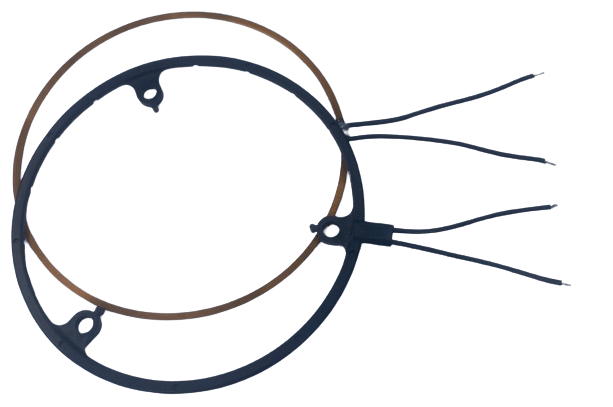

- Application: Free Standing Bonded Coil (Air Coil) Overmold

- Automotive airbag deployment system

- Structure and protection of large diameter / fine gauge bondable magnet wire

- Superior consistency vs. separate housing

- Application: Automotive Starter Motor

- Thermal rise reduction through thermally conductive plastic overmold

- 70% improvement in results from Battery Run Down Test

Get in Touch with Our Experts

For more information or to discuss your project, reach out to Encap Technologies. Our team is ready to assist you with advanced thermoplastic encapsulation solutions tailored to your needs.