Rotors – Magnet Fixing / Overmolding

Decades of experience in challenging automotive and non-automotive environments. Thermoplastic magnet fixing enables proven, reliable, cost effective manufacturing.

- Significantly lower cost than other methods

- Excellent rare earth magnet cost position

- No cure time. No curing. Zero.

- Eliminates messiness of glue

- Uniform mass distribution / better balance

- Can use thermally conductive / electrically insulative materials

- Fixing of either unmagnetized or magnetized magnets

- Free standing rotors and stackable hubs or rings

- Use of "loose laminations" for improved cost

- Integration of shaft / Can achieve double insulation

Magnet Fixing - Rotors

- Application: Hybrid Electric Motor

- 64 overmolded neodymium magnets locked in place

- 190mm diameter, 90mm total stack height

- Dimensional stability and chemical resistance in various fluids and hydrocarbons

- Multiple lam stack heights for different programs

Magnet Fixing - Rotors

- Application: Automotive Pumps

- Wet Rotor application, used in cooling fluids, transmission fluids, oils

- Overmolded rare earth magnets locked in place

- Dimensional stability and chemical resistance in various fluids and hydrocarbons

- Multiple lam stack heights for different programs

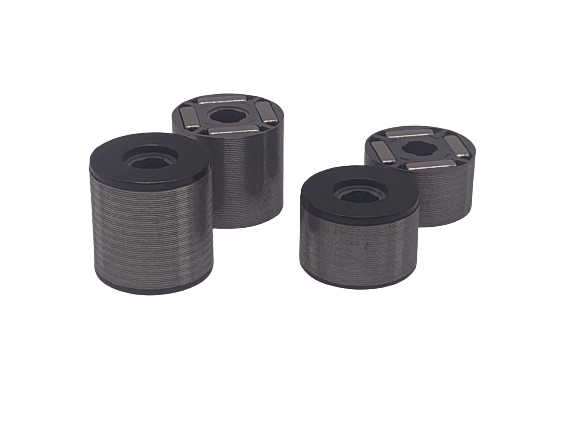

Magnet Fixing - Rotors

- Application: Irrigation Pump

- Overmolding of already magnetized magnets

- Molded-in steel shaft

- Overmolded rare earth magnets locked in place

- Loose Laminations

- Reduced lam stack capital cost and part cost

- Improved electromagnetic performance

- 54mm height, 20mm diameter – High Aspect Ratio

Get in Touch with Our Experts

For more information or to discuss your project, reach out to Encap Technologies. Our team is ready to assist you with advanced thermoplastic encapsulation solutions tailored to your needs.