Stator Ground Insulation

Molded Ground Insulation provides robust, high temperature electrical insulation between magnet wires and the steel laminations, but also can provide:

- Winding Aids

- Simplified Manufacturing / Cost Reduction

- Component Reduction

- Integration of Terminal Pockets

- Integration of IDCs (Insulation Displacement Connectors)

- Potential advantages of use of "loose" laminations

Ground Insulation For Stator Lamination Stack

- Application: Industrial Blower

- Loose Laminations

- Lower cost lam stack capital and part cost

- Improved electromagnetic performance

- Eliminated pinhole issues in powder coat epoxy insulation

- Molded-in winding aids, flanges, and PCB standoff features

- Component reduction

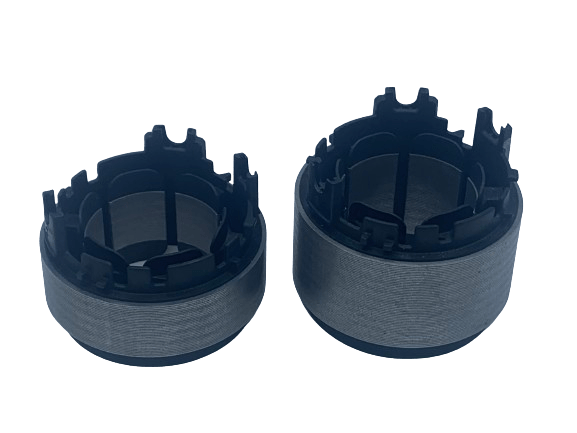

Ground Insulation For Stator Lamination Stack

- Application: Automotive Pumps

- Multiple lam stack heights in same injection mold

- Same tool for different automotive programs/applications

- Molded-in terminal pockets, winding aids, and flanges

- Used in BEV, PHEV, and ICE applications

- Component reduction

Get in Touch with Our Experts

For more information or to discuss your project, reach out to Encap Technologies. Our team is ready to assist you with advanced thermoplastic encapsulation solutions tailored to your needs.