Stator Segment Ground Insulation

Stator Segments enable improved motor performance and reduced costs, however segmentation can add manufacturing complexity and traditional slot lines are problematic and difficult to handle. Overmolded Ground Insulation mitigates these manufacturing challenges.

- Why Segmented Stators

- Improved power density

- Greater winding slot fill

- Less steel scrap / Lower part cost

- Lower capital costs

- Independent, optimized steel choice between stator & rotor

- Why Overmolded Ground Insulation?

- Reliable ground insulation

- Incorporation of Winding Aids

- Simplified manufacturing / Cost Reduction

- Component Reduction

- Integration of Terminal Pockets

- Integration of IDCs (Insulation Displacement Connectors)

- Potential advantages of use of "loose" laminations

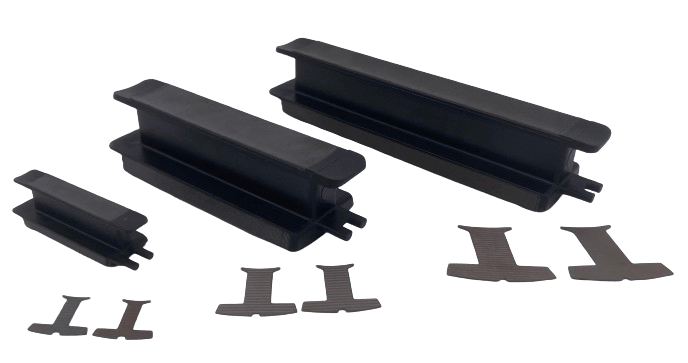

Stator Segment with Overmolded Plastic Ground Insulation

- Application: EPS (Electric Power Steering) Motor

- Winding aids on all sides

- Adjustable for multiple stack heights

- High temperature, dimensional stability

- Interlocked laminations

- Increased power density with segmented stator

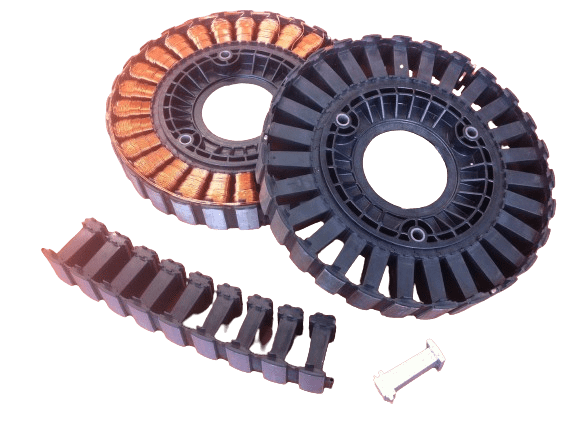

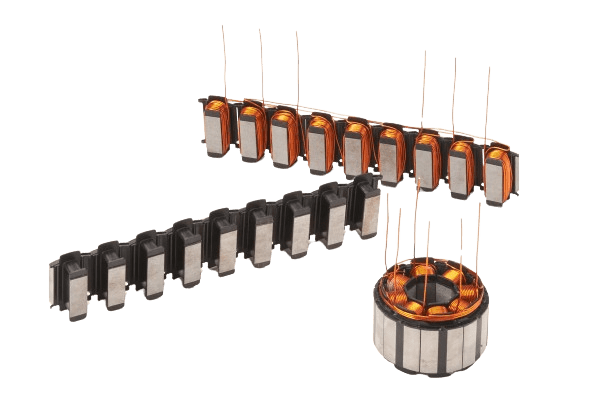

Overmolded Stator Segment Strip

- Application: Washing Machine

- 9 Segments molded at one time

- Plastic links each segment to the next

- Flexes out to wind and coils in for assembly

- Outer Rotor Design (also known as an “Outrunner” or “External Rotor”)

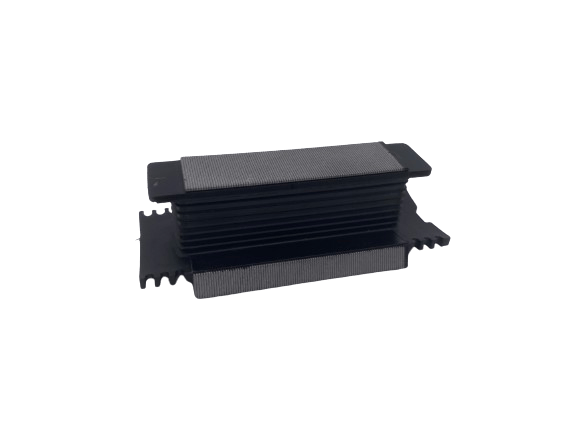

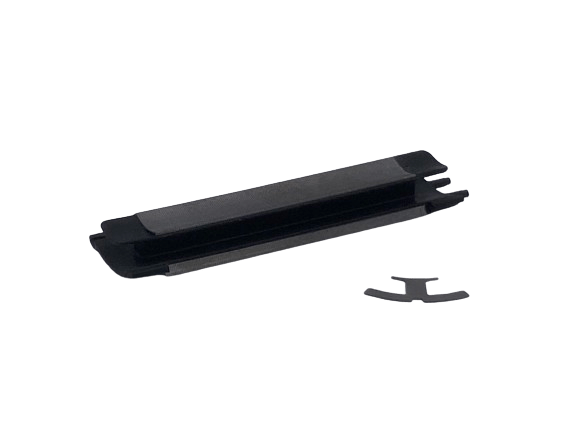

Stator Segment with Overmolded Plastic Ground Insulation

- Application: High Efficiency Solar Pump

- Loose Laminations

- Reduced lam stack capital cost and part cost

- Improved electromagnetic performance

- Eliminates paper slot liners

- Simplifies assembly with ground insulation

- Thin wall, long flow

- Increased power density with stator segments

Stator Segment with Overmolded Plastic Ground Insulation

- Application: Robot Motors

- Loose Laminations

- Lower cost lam stack capital and part cost

- Improved electromagnetic performance

- Eliminates paper slot liners

- UL1446 Pre-approved Electrical Insulation System (EIS)

T-Link® Stator Segmentation System

- Plastic links segments

- Linear array enables single strand winding and eliminates wire interconnects

- Significant steel scrap reduction

- Precision winding increases slot fill

- Gamma induced variation in stack height is reduced

Get in Touch with Our Experts

For more information or to discuss your project, reach out to Encap Technologies. Our team is ready to assist you with advanced thermoplastic encapsulation solutions tailored to your needs.